Plato and the laser cutter

How are artists responding to these divisive times?

Sarah Bryant's most recent work, "The Radiant Republic", began with the contemplation of the flexible and vulnerable nature of truth and led her to explore how Plato and Le Corbusier use the design of a city to describe the ethics of man.

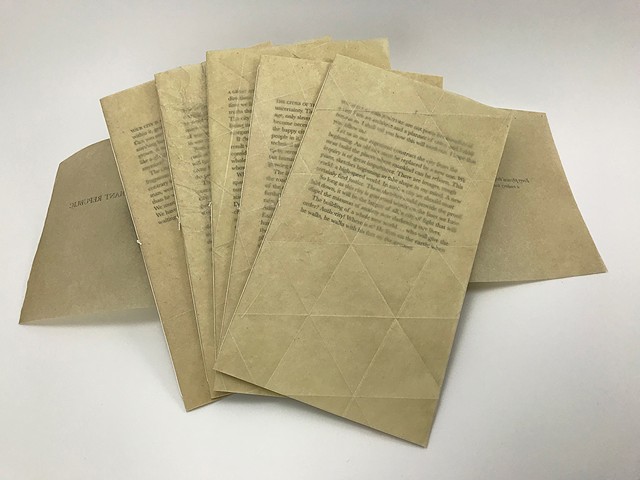

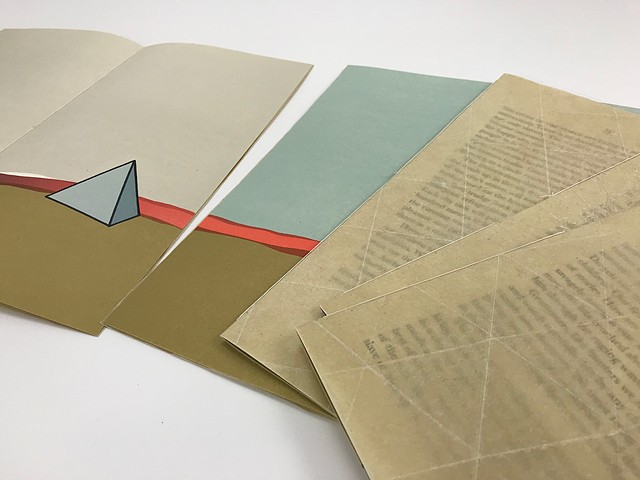

And what, you may ask, does this have to do with laser cutting? As with many projects I work on, the laser cut element is a piece of a larger whole.Sarah's project was complex: it included five letterpress books printed on Handmade Belgian Flax paper with interlocking images and cast concrete shapes housed in a laser cut box base (that’s where I come in!) with a printed Dubletta book cloth top.

In this post I share with you the laser cut box made for "The Radiant Republic" and walk you through how I collaborate with artists to help them bring the laser cut components of their projects to life.

When book artist Sarah Bryant first contacted me last spring, I was ecstatic. She didn't know that I had been following her work for years and she was on my secret list of artists I want to work with.

Our collaboration started with a phone consultation in which Sarah described her project, which called for 50 laser cut boxes. Even when laser cutting is a piece of a much larger project, it's important for me to understand the project as a whole. Whether addressing conceptual concerns or physical construction, I can solve a problem more easily when I can see the big picture. In the case of Sarah's project, the box needed to be strong enough to hold several concrete shapes. Had I not understood this from the outset, we could have had some real problems down the line.

We talked about her different options both for the laser cut box itself and for how much involvement she wanted to have in the laser cutting process.

Step 1: Mock-Up

There comes a point in every artist's life when you realize that just because you can, doesn't mean you should.

Yes, Sarah could have spent hours figuring out how to make a laser-ready file. Or, even better, she could save time by building a mock-up for me to use to create the laser-ready file for her. So that's what we decided to do.

Step 2: Prototype #1

Part of the file making process for laser cut boxes is figuring out the kerf, since the laser removes a certain amount of material when it cuts. I knew from experience that f I didn't compensate for this in the file for Sarah's prototype, the dovetail joints wouldn't be tight enough to hold the box together.

Because laser cutting is a heat-based method, and wood thickness and density can vary, figuring out the kerf can take several rounds of adjusting the file and testing. Once I got the right fit—snug, but not too snug—I cut the first prototype and sent it off to Sarah.

mock-up (left) - prototype (right) - kerf tests (front)

Step 3: Prototype #2

Sarah had several things to figure out when she received the first proof. How did the design work with the other elements? Was the box strong enough to hold the concrete shapes? Did the design of the dovetails detract or enhance the piece? What was the most efficient way to glue the box together?

For Prototype #2 we adjusted the number of dovetails. Once Sarah confirmed that this didn't compromise the strength of the box, I went into production.

Step 4: Production

Production is pretty straightforward, right? The answer is yes, if you plan for it.

Anytime you are working with a natural material, such as wood, there will be variations that will affect the laser cutting. Expect to buy 5-10% more material than you think you need. For this project we were using Baltic birch plywood which, because of occasional hard spots, has areas that cannot be cut out fully.

To make 50 complete sets, I threw a few extra sheets into the materials order, to be on the safe side.

And here is the final piece!

Sarah Bryant, The Radiant Republic

Dimensions: 10.5” x 6.5” x 4.5”

Weight: Just under 8 pounds

Materials: Rives Heavyweight paper, Handmade Belgian Flax paper (commissioned from the Morgan Conservatory), Baltic Birch Plywood, glass, cement, binders board, and Dubletta book cloth.